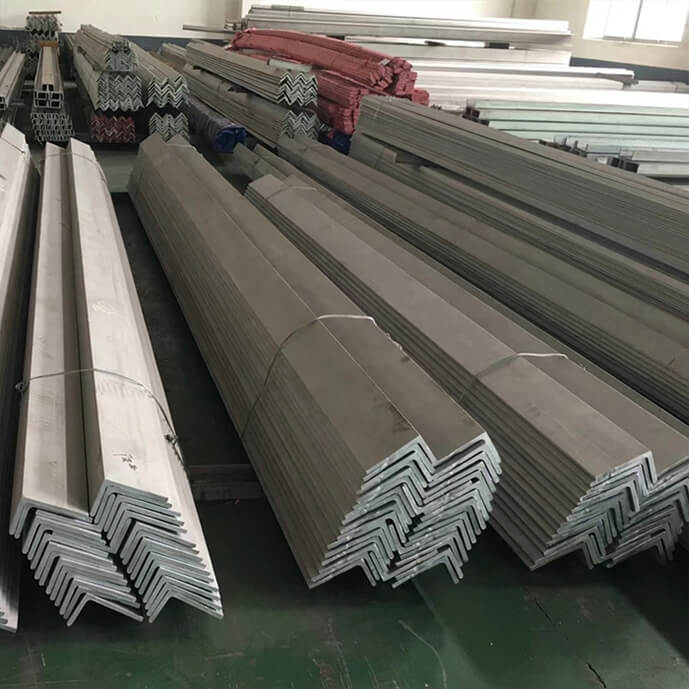

202 stainless steel angles :

202 stainless steel is a kind of 200 series stainless steel, the national standard model is 1Cr18Mn8Ni5N. 202 stainless steel is widely used in building decoration, municipal engineering, highway guardrails, hotel facilities, shopping malls, glass handrails, public facilities and other places.

202 stainless steel is one of the 200 series stainless steels, the national standard model is 1Cr18Mn8Ni5N. The 200 series stainless steel belongs to low nickel and high manganese stainless steel with a nickel content of about 8% and a manganese content of about 8%. It is a nickel-saving stainless steel.

304 Stainless Steel Angles :

The thinner section have higher strength values. The specification of the section is the A240 for pressure vessel and high temperature applications. The ASTM A240 SS 304 section can withstand high temperatures up to 870 degrees Celsius. The section are used for this reason in evaporators, heat exchangers and in other high temperature applications. The Stainless Steel 304 Plate is also used in drums, barrels, dairy equipment, food processing and in hospital equipment.

This is the most cost effective grade of steel. So the 304 Stainless Steel section Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The section and UNS S30400 Stainless Steel Strip Specification varies and the applications differ for the different versions of the material. The low carbon version, 304L section are very good for welding applications as they have less carbide precipitation and less localized corrosion. The ASME SA240 Stainless Steel 304 Coil Thickness ranges up to 200mm and the width and the length ranges widely depending on the application requirements as well. Please contact us for more information and prices.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 304 | S30400 | 304S15 | 58E | 1.4301 | X5CrNi18-10 | 0Cr18Ni9 | SUS304 |

Stainless Steel 304 Chemical Comppsition :

304L Stainless Steel Angles :

The thinner section have higher strength values. The specification of the section is the A240 for pressure vessel and high temperature applications. The ASTM A240 SS 304 section can withstand high temperatures up to 870 degrees Celsius. The section are used for this reason in evaporators, heat exchangers and in other high temperature applications. The Stainless Steel 304 Plate is also used in drums, barrels, dairy equipment, food processing and in hospital equipment.

This is the most cost effective grade of steel. So the 304 Stainless Steel section Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The section and UNS S30400 Stainless Steel Strip Specification varies and the applications differ for the different versions of the material. The low carbon version, 304L section are very good for welding applications as they have less carbide precipitation and less localized corrosion. The ASME SA240 Stainless Steel 304 Coil Thickness ranges up to 200mm and the width and the length ranges widely depending on the application requirements as well. Please contact us for more information and prices.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 304L | S30403 | 304S12 | - | 1.4307 | X2CrNiN18-9 | 00Cr19Ni10 | SUS304L |

Stainless Steel 304L Chemical Comppsition :

316 stainless steel angles :

316L is widely used in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative steel of 18-8 type austenitic stainless steel, with 2 to 3% Mo element added. On the basis of 316L, many steel grades are also derived. For example, 316Ti is derived from adding a small amount of Ti, 316N is derived from adding a small amount of N, and 317L is derived from increasing the content of Ni and Mo.

Most of the existing 316L on the market is produced in accordance with American standards. For cost considerations, steel mills generally keep the Ni content of their products as low as possible. The American standard stipulates that the Ni content of 316L is 10-14%, and the Japanese standard stipulates that the Ni content of 316L is 12-15%. According to the minimum standard, there is a 2% difference in Ni content between the American standard and the Japanese standard, which is still quite huge in terms of price. Therefore, customers still need to see clearly when purchasing 316L products, whether the product is based on ASTM or JIS standards.

Tensile strength σb (MPa): ≥480

Conditional yield strength σ0.2 (MPa): ≥177

Elongation δ5 (%): ≥40

Reduction of area ψ (%): ≥60

Hardness: ≤187HB; ≤90HRB; ≤200HV

Density: 7.98g/cm3;

Specific heat ratio (20℃): 0.502J/(g*K)

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 316 | S31600 | 316S31 | 58H,58J | 1.4401 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 | SUS 316 |

Stainless Steel 316 Chemical Comppsition:

316L stainless steel angles :

316L is widely used in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative steel of 18-8 type austenitic stainless steel, with 2 to 3% Mo element added. On the basis of 316L, many steel grades are also derived. For example, 316Ti is derived from adding a small amount of Ti, 316N is derived from adding a small amount of N, and 317L is derived from increasing the content of Ni and Mo.

Most of the existing 316L on the market is produced in accordance with American standards. For cost considerations, steel mills generally keep the Ni content of their products as low as possible. The American standard stipulates that the Ni content of 316L is 10-14%, and the Japanese standard stipulates that the Ni content of 316L is 12-15%. According to the minimum standard, there is a 2% difference in Ni content between the American standard and the Japanese standard, which is still quite huge in terms of price. Therefore, customers still need to see clearly when purchasing 316L products, whether the product is based on ASTM or JIS standards.

Tensile strength σb (MPa): ≥480

Conditional yield strength σ0.2 (MPa): ≥177

Elongation δ5 (%): ≥40

Reduction of area ψ (%): ≥60

Hardness: ≤187HB; ≤90HRB; ≤200HV

Density: 7.98g/cm3;

Specific heat ratio (20℃): 0.502J/(g*K)

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 316L | S31603 | 316S11 | 1.4404 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 | SUS316L | |

Stainless Steel 316 Chemical Comppsition:

310S stainless steel angles :

310S stainless steel has good high temperature resistance. When the temperature exceeds 800 [1], it begins to soften, the allowable stress begins to continue to decrease, and the maximum service temperature is 1200°C. Due to the high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel pipes are specially used to manufacture electric furnace tubes. The austenitic stainless steel adds carbon After the content, the strength is improved due to its solid solution strengthening effect. The chemical composition of austenitic stainless steel is based on chromium and nickel with the addition of elements such as molybdenum, tungsten, niobium, and titanium. Because of its face-centered cubic structure, Therefore, it has high strength and creep strength at high temperature.

Hardness (HB): ≤187

Tensile strength (бb) (Mpa): ≥515

Yield strength (σs) (Mpa): ≥205

Elongation (δ)%: ≥35

Area reduction (ψ)%: ≥50

1. Recommended heat treatment system: 1030 degrees Celsius -1180 degrees Celsius, rapid cooling;

2. Mechanical properties include (1.) Tensile strength: not less than 520; (2.) Specified non-proportional extension strength: not less than 205; (3.) Elongation after fracture: not less than 35;

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 310S | S310S00 | 310SS37 | 56C | 1.4021 | X20Cr13 | 2CR13 | SUS 310S |

Stainless Steel 310S Chemical Comppsition:

321 Stainless Steel Angles :

to resistance to oxidizing acid media corrosion, this type of steel can also be resistant to corrosion by sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains elements such as Mo and Cu. If the carbon content in this type of steel is less than 0.03% or contains Ti and Ni, its resistance to intergranular corrosion can be significantly improved. High-silicon austenitic stainless steel has good corrosion resistance to concentrated nitric acid. As austenitic stainless steel has comprehensive and good comprehensive properties, it has been widely used in various industries.

321 austenitic stainless steel has good corrosion resistance in the atmosphere and is widely used in petrochemical, electric power, bridge and automobile industries [1]. However, the "stainlessness" of stainless steel is not absolute. Due to the special service environment, stainless steel will also corrode. Factors such as medium concentration, pH value, and temperature will have a greater impact on the corrosion resistance of stainless steel. For example, if used for a long time within the sensitization temperature range of 450~850℃, stainless steel will undergo intergranular corrosion. The mechanism is that C combines with Cr at the grain boundary to form Cr23C6 and precipitate, which reduces the Cr content at the grain boundary. This is the so-called "chromium depletion". The Cr element is one of the main elements that inhibit intergranular corrosion. When the Cr content at the grain boundary is less than 12%, the probability of intergranular corrosion will increase. [1]

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

409L Stainless Steel Angles :

409L stainless steel has excellent corrosion resistance and is suitable for prolonging the life of automobiles and reducing the weight of automobiles. As an environmentally friendly material that can be recycled and reused, major automobile manufacturers such as GM, Ford, Volkswagen, DaimlerChrysler and other major automobile manufacturers use stainless steel in their exhaust systems. . The automobile exhaust system treats the high-temperature, high-speed combustion exhaust gas generated by the automobile engine and discharges it to the outside of the automobile. The main function of the exhaust system is to reduce vibration and noise, and after reburning the exhaust gas, it is converted into clean gas. Automobile exhaust system is the longest part of automobile components. The system has to withstand extreme temperature changes (-20~850℃) and high-frequency vibration of high-temperature and high-speed exhaust gas, and it is in the car with the largest changes and the most complex In the environment, the temperature limit that 409L can withstand is (-20~650℃).

Due to the increasingly stringent environmental protection standards for automobile exhaust, the increase in short-distance urban driving, and the spread of snow removal agents in winter, the exhaust system usage standards have also become increasingly strict. From the European II-Euro IV standards, traditional steel materials cannot meet the requirements. Technical requirements, high-end motorcycle exhaust system has adopted 409L material. The amount of 409L stainless steel used in each vehicle is 35KGS-65KGS.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 409 | S40900 | 409S19 | 1.4512 | X6CrTi12 | 022Cr11Ti | SUS 409L | |

Stainless Steel 409L Chemical Comppsition:

430 Stainless Steel Angles :

430 stainless steel is a general-purpose steel with good corrosion resistance. It has better thermal conductivity than austenite, a smaller thermal expansion coefficient than austenite, heat fatigue resistance, addition of stabilizing element titanium, and good mechanical properties at the weld. 430 stainless steel is used for building decoration, fuel burner parts, household appliances, and home appliance parts. 430F is a steel grade with free-cutting performance added to 430 steel. It is mainly used for automatic lathes, bolts and nuts. 430LX adds Ti or Nb to 430 steel, reduces C content, improves processing performance and welding performance, and is mainly used for hot water tanks, hot water supply systems, sanitary appliances, household durable appliances, bicycle flywheels, etc.

Because of its chromium content, it is also called 18/0 or 18-0. Compared with 18/8 and 18/10, it contains slightly less chromium, and the hardness is correspondingly lower.

430 stainless steel has the ability to resist oxidation to corrosion, but has a tendency to intergranular corrosion.

430 stainless steel wire is widely used in the axis.

Because it is safe and non-toxic, it is widely used in food and tableware.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 430 | S43000 | 430S17 | 60 | 1.4016 | X8Cr17 | 1Cr17 | SUS 430 |

Stainless Steel 430 Chemical Comppsition:

444 Stainless Steel Angles:

The 444 steel grade is a high-alloy ferritic stainless steel. Compared with the commonly used steel grade SUS430: 1. The chromium content is about 1.0% higher, and the alloy element molybdenum (Mo) is added, so the steel grade has good pitting corrosion resistance, Crevice corrosion, stress corrosion resistance, its corrosion resistance is even better than SUS304 and SUS316 in some areas. 2. Added stabilizing elements such as titanium (Ti), niobium (Nb), zirconium (Zr), so the steel has Good resistance to intergranular corrosion and high temperature oxidation resistance.

Stainless steels are high-alloy steels that have excellent corrosion resistance in comparison with other steels as they contain more chromium.

Based on their crystalline structure, stainless steels are divided into three groups, namely, martensitic, austenitic and ferritic steels. A combination of martensitic and ferritic steels forms a fourth group known as precipitation-hardened steels.

The following datasheet provides an overview of grade 444 stainless steel.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 444 | S44400 | 1.4021 | 1.4521N | 00Cr18Mo2 | SUS 444 | ||

Stainless Steel 444 Chemical Comppsition:

904L Stainless Steel Angles :

904L super austenitic stainless steel is a low-carbon, high-nickel, molybdenum austenitic stainless and acid-resistant steel, which is a proprietary material imported from France H·S. It has good activation-passivation transformation ability, excellent corrosion resistance, good corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid, and phosphoric acid, and good corrosion resistance in neutral chloride-containing media It has good pitting corrosion resistance and good resistance to crevice corrosion and stress corrosion. It is suitable for sulfuric acid of various concentrations below 70°C, and has good corrosion resistance in acetic acid at any concentration and at any temperature and the mixed acid of formic acid and acetic acid under normal pressure.

* Petroleum and petrochemical equipment, such as reactors in petrochemical equipment, etc.

* Sulfuric acid storage and transportation equipment, such as heat exchangers, etc.

* Power plant flue gas desulfurization device, the main use parts are: the tower body of the absorption tower, flue, gate plate, internal parts, spray system, etc.

* Scrubber and fan in the organic acid treatment system.

*Sea water treatment equipment, sea water heat exchanger, paper industry equipment, sulfuric acid, nitric acid equipment, acid making, pharmaceutical industry and other chemical equipment, pressure vessels, food equipment.

*Pharmaceutical factories: centrifuges, reactors, etc.

*Plant food: soy sauce cans, cooking wine, salt cans, equipment and dressings.

*It is a matching steel grade for the strong corrosive medium of dilute sulfuric acid 904L

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 904L | N08904 | 904S13 | 1.4539 | X1NiCrMoCuN25-20-54 | 00Cr20Ni25Mo4.5Cu | SUS 904L | |

Stainless Steel 904L Chemical Comppsition:

2205 Stainless Steel Angles :

· Pressure vessels, high-pressure storage tanks, high-pressure pipes, heat exchangers (chemical processing industry).

· Oil and gas pipelines, heat exchanger fittings.

· Sewage treatment system.

· Pulp and paper industry classifiers, bleaching equipment, storage and processing systems.

· Rotary shafts, press rolls, blades, impellers, etc. under high-strength and corrosion-resistant environments.

· Cargo boxes of ships or trucks

· Food processing equipment

Duplex stainless steel 2205 standard number: ASTM A240/A240M--01 duplex stainless steel 2205 alloy is a duplex stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good overall and local stress corrosion resistance.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 2205 | S32205 | 1.4462 | X2CrNiMoN | 022Cr23Ni5Mo3N | SUS 2205 | ||

Stainless Steel 2205 Chemical Comppsition: