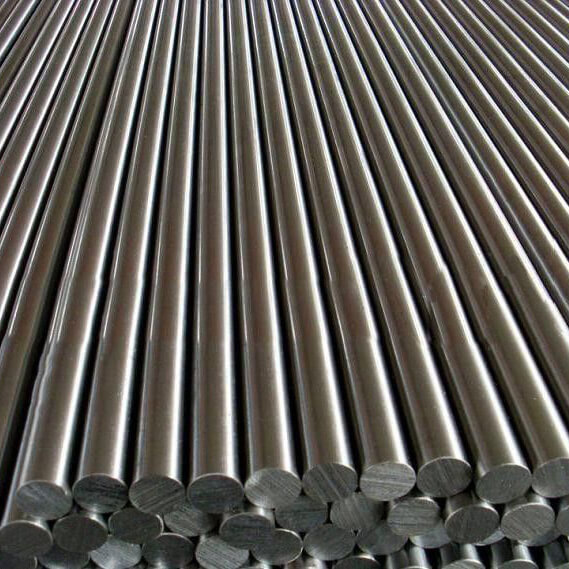

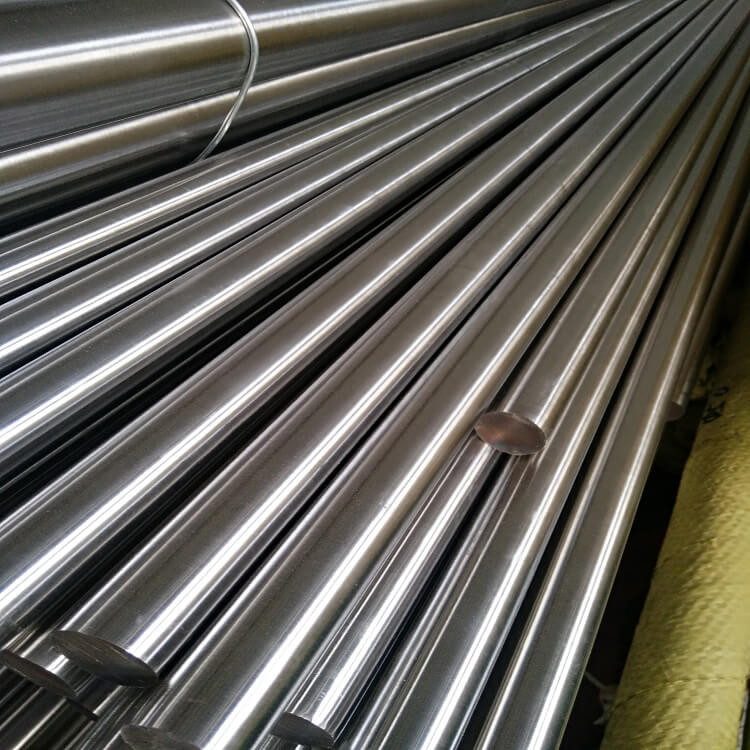

201 Stainless Steel Bar Rod :

Type 201 stainless steel is a mid-range product with a variety of useful qualities. While it is ideal for certain uses, it is not a good choice for structures that may be prone to corrosive forces such as saltwater.

Type 201 is used to produce a range of household appliances, including sinks, cooking utensils, washing machines, windows, and doors. It is also used in automotive trim, decorative architecture, railway cars, trailers, and clamps. It is not recommended for structural outdoor applications because of its susceptibility to pitting and crevice corrosion.

Grade 201 stainless steel has good formability, corrosion resistance, and fabricability. It is similar to that of 301 stainless steel. The following datasheet gives more details about grade 201 stainless steel.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 201 | - | - | 1.4372 | - | - | 1Cr17Mn6Ni5N | SUS201 |

Stainless Steel 201 Chemical Comppsition :

202 Stainless Steel Bar Rod :

The machinability of grade 202 stainless steel produces long, gummy chips. Machining can also be performed in the annealed condition. For heat treatment, the material has to be soaked at 1038°C (1900°F) for 30 min and cooled below 16°C (60°F) for full martensite transformation. The material can be welded by common fusion and resistance methods; however, this steel should not be joined using oxyacetylene welding method. The recommended filler metal is AWS E/ER630. Forging can be done by pre-soaking for 1 h at 1177°C (2150°F). Forging below 1010°C (1850°F) is not advisable

Both grades 304, as well as grade 202 stainless steel, belong to the austenitic class. This means that the microstructure of both stainless steel alloys is face-centered cubic. Since grade 304 is an alloy that falls under the 300 series stainless steel, this alloy inherits its austenitic structure primarily the inclusion of a higher content of nickel added to its alloy. On the other hand, grade 202 falls under the 200 series stainless steel. Grades that belong to the 200 series stainless steel, tend to substitute elements such as manganese and nitrogen in their chemistry, as an effective alternative for the element nickel. This being said, it is interesting to note that there still is a small inclusion of nickel content in their alloys.

Stainless Steel 202 Chemical Comppsition :

304 Stainless Steel Bar Rod :

The higher operating temperatures for ASTM A276 Type 304 Rod are possible because of the high melting point of 1400 degrees Celsius of the material. The bars are made in different models, specifications and types such as the ASTM A479 GR 304 Bright Bar and SS 304 Round Bar. The A479 is a specification that covers bars of hot rolled, cold drawn and pressure vessel bars. The pressure vessel specification mandates the SS UNS S30400 Hot Rolled Bar to be able to handle high pressures. The material can come in varying dimensions.

The 304 Stainless Steel Bar is used mostly for its high geometrical strength. The applications include construction and other commercial applications as well. The strength, heat resistance and corrosion resistance are all the result of the composition. The material includes carbon, manganese, phosphorus, silicon, sulfur and chromium and nickel. Please contact us for more information on the SS 304 Bar and other types as well as their pricing.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 304 | S30400 | 304S15 | 58E | 1.4301 | X5CrNi18-10 | 0Cr18Ni9 | SUS304 |

Stainless Steel 304 Chemical Comppsition :

304L Stainless Steel Bar Rod :

The higher operating temperatures for ASTM A276 Type 304L Rod are possible because of the high melting point of 1400 degrees Celsius of the material. The bars are made in different models, specifications and types such as the ASTM A479 GR 304L Bright Bar and SS 304L Round Bar. The A479 is a specification that covers bars of hot rolled, cold drawn and pressure vessel bars. The pressure vessel specification mandates the SS UNS S30403 Hot Rolled Bar to be able to handle high pressures. The material can come in varying dimensions.

The 304L Stainless Steel Bar is used mostly for its high geometrical strength. The applications include construction and other commercial applications as well. The strength, heat resistance and corrosion resistance are all the result of the composition. The material includes carbon, manganese, phosphorus, silicon, sulfur and chromium and nickel. Please contact us for more information on the SS 304 Bar and other types as well as their pricing.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 304 | S30400 | 304S15 | 58E | 1.4301 | X5CrNi18-10 | 0Cr18Ni9 | SUS304 |

Stainless Steel 304L Chemical Comppsition :

310S Stainless Steel Bar Rod :

Grade 310S stainless steel can be welded using fusion or resistance welding techniques. Oxyacetylene welding method is not preferred for welding this alloy.

Grade 310S stainless steel can be headed, upset, drawn, and stamped even though it has high work hardening rate. Annealing is performed after cold working in order to reduce internal stress.

Grade 310S stainless steel does not react to heat treatment. Strength and hardness of this alloy can be increased by cold working.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 310S | S31008 | - | - | 1.4951 | - | 0Cr25Ni20 | SUS 310S |

Stainless Steel 310S Chemical Comppsition :

Stainless Steel 310S Mechanical Properties :

316 Stainless Steel Bar Rod :

Grade 316L, the low carbon version of 316 and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). Grade 316H, with its higher carbon content has application at elevated temperatures, as does stabilised grade 316Ti.

316 is usually regarded as the standard “marine grade stainless steel”, but it is not resistant to warm sea water. In many marine environments 316 does exhibit surface corrosion, usually visible as brown staining. This is particularly associated with crevices and rough surface finish.

Product advantage

1. Environmental protection: It can effectively reduce environmental pollution.

2. Corrosion resistance: stain resistance, acid resistance, corrosion resistance, wear resistance, no radioactivity.

3. Surface cleaning: the surface of the product is smooth and compact, not easy to be polluted by dust, with good self-cleaning.

4. Easy maintenance: Easy to repair minor damage.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

316L Stainless Steel Bar Rod :

Grade 316L, the low carbon version of 316 and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). Grade 316H, with its higher carbon content has application at elevated temperatures, as does stabilised grade 316Ti.

316 is usually regarded as the standard “marine grade stainless steel”, but it is not resistant to warm sea water. In many marine environments 316 does exhibit surface corrosion, usually visible as brown staining. This is particularly associated with crevices and rough surface finish.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 316L | S31603 | 316S11 | - | 1.1104 | X2CrNiMo17-12-2 | 022Cr17Ni12Mo2 | SUS316L |

Stainless Steel 316L Chemical Comppsition:

321 Stainless Steel Bar Rod :

A limitation with 321 is that titanium does not transfer well across a high-temperature arc, so it is not recommended as a welding consumable. In this case grade 347 is preferred - the niobium performs the same carbide stabilization task but can be transferred across a welding arc. Grade 347 is, therefore, the standard consumable for welding 321. Grade 347 is only occasionally used as parent plate material.

Grade 321H is a modification of 321 with higher carbon content, to provide improved high-temperature strength.

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 321 | S32100 | 321S31 | 58B | 1.4541 | X6CrNiTi18-10 | X10CrNiTi189 | SUS 321 |

Stainless Steel 321 Chemical Comppsition:

409L Stainless Steel Bar Rod :

Grade 409 steels are also available in highly stabilized forms, such as grades S40930, S40920 and S40910. The stability of these grades is provided by the presence of niobium, titanium, or both, in the composition of stee

The typical chemical compositional ranges of grade 409 stainless steels are given below:

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 409L | S40900 | 409S19 | - | 1.4512 | X6CrTi12 | 0Cr11Ti | SUS 409L |

Stainless Steel 409L Chemical Comppsition:

430 Stainless Steel Bar Rod :

Stainless Steel Round Bar 430 is normally used for architectural, machine, automotive, natural gas/petroluem/oil, thermal, and furniture applications. 430 stainless is notable for having a corrosion resistance similar to nickel stainless steels when exposed to atmospheric and mildly corrosive environments. It is not hardenable, but has high strength and is easily drawn, bent, formed and worked.

Type 430 Stainless Steel is perhaps the most popular non-hardenable ferritic stainless steel available. Type 430 is known for good corrosion, heat, oxidation resistance, and its decorative nature.

It is important to note that when well polished or buffed its corrosion resistance increases. All welding must occur at higher temperatures, but it is easily machined, bent, and formed. Thanks to this combination it is used in a number of different commercial and industrial applications including:

Furnace combustion chambers

Automotive trim and molding

Gutters and downspouts

Nitric acid plant equipment

Oil and Gas refinery equipment

Restaurant equipment

Dishwasher linings

Element supports and fasteners

Stainless steel is a kind of alloy steel, with smooth surface, high weldability, corrosion resistance, polishing, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into stainless steel, iron oxygen stainless steel, Martengsitt stainless steel and duplex stainless steel by structural state.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 430 | S43000 | 430S17 | 60 | 1.4016 | X8Cr17 | 0Cr18Ni9 | SUS 430 |

Stainless Steel 430 Chemical Comppsition :

Stainless Steel 430 Mechanical Properties :

444 Stainless Steel Bar Rod :

444 stainless steel plastic, toughness is good, suitable for stretching, rolling forming and stamping manufacturing.Especially the application of corrosion resistance is the most excellent, in the high chloride medium corrosion resistance is better than ordinary ferrite stainless steel and Olympic stainless steel, generally do not produce chloride stress corrosion cracking.When Ti and Mo elements are added, the resistance to pore and crevice corrosion is improved.The steel can be welded by the method of welding ordinary stainless steel.This kind of steel is especially suitable for food processing equipment, heat exchanger, water heater tank, water storage tank, solar energy collection panel, etc.

444 steel belongs to high alloy ferritic stainless steel, compared with the commonly used steel SUS430:1.The chromium content is about 1.0% high, and the alloying element molybdenum (Mo) is added, so the steel has good resistance to pitting corrosion, crevices corrosion, stress corrosion ability, its corrosion resistance in some areas even better than SUS304 and SUS316.2. Add titanium (Ti), niobium (Nb), zirconium (Zr) and other stabilized elements, so the steel has good intergranular corrosion resistance and high temperature oxidation resistance.

| Grade | UNS No. | Old British | Euronorm | China GB | Japanese JIS | ||

| BS | EN | No. | Name | ||||

| 444 | S44400 | - | 1.4521N | - | - | 00Cr18Mo2 | SUS 444 |

Stainless Steel 444 Chemical Comppsition:

Stainless Steel 444 Mechanical Properties: